Executive Summary

Addition of 10% and 20% of TOPAS® Elastomer E-140 into TOPAS® COC 6015S-04 and 6017S-04 was studied for its impact on film properties. The 20% loading level improved the bending toughness of 6015S-04 by an average 22x and 6017S-04 by an average of 10x. These improvements in toughness are offset by increases in haze, linear decreases in tensile modulus, and increases in birefringence. Tensile strength at break in the transverse direction was decreased in both resins when using a 20% loading of Elastomer E-140, though this may be because these films exhibited necking behavior during tensile testing.

Introduction

TOPAS® cyclic olefin copolymers (COC) are rigid, amorphous polyolefins with glass transition temperatures (Tg’s) ranging from 65°C to 178°C. The high Tg of COC results in high modulus and heat resistance in thin films. However, sometimes an application needs to couple the high modulus and heat resistance of TOPAS® COC resins with a little more toughness. Blending in some TOPAS® Elastomer E-140 can help improve the durability of COC while maintaining the regulatory compliance for which TOPAS® COC is known.

Materials

TOPAS® Elastomer E-140 is a semi-crystalline ethylene-norbornene copolymer that can be used on its own or as a blend component with rigid TOPAS® COC or other polyolefins to finely tune performance characteristics. Elastomer E-140 is distinct from other COC resins in that it has a melting temperature as a semi-crystalline polymer, and that it has a tensile modulus around 50MPa rather than above 2000MPa for COC grades. TOPAS® COC are amorphous polyolefins with high Tg’s relative to traditional polyolefins. And because COC resins are amorphous, they do not have a melt temperature but are instead classified by their glass transition temperatures.

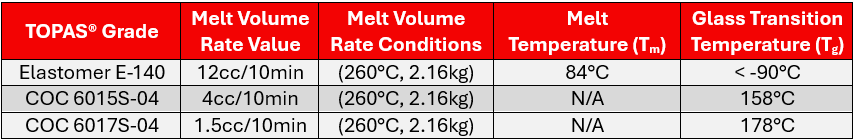

Two grades of TOPAS® COC were used in this study alongside Elastomer E-140: 6015S-04 and 6017S-04. The Tg, Tm data, melt volume rate for the two amorphous COC resins and Elastomer E-140 are given in Table 1, below.

Table 1: Melt volume rate, melt temperature, and glass transition temperature for the three TOPAS® grades used in this study. The COC resins are amorphous and do not have a melt temperature.

Results

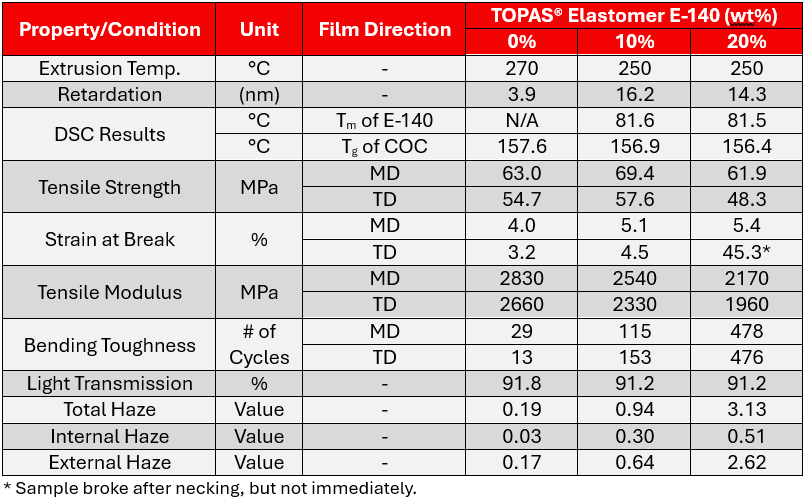

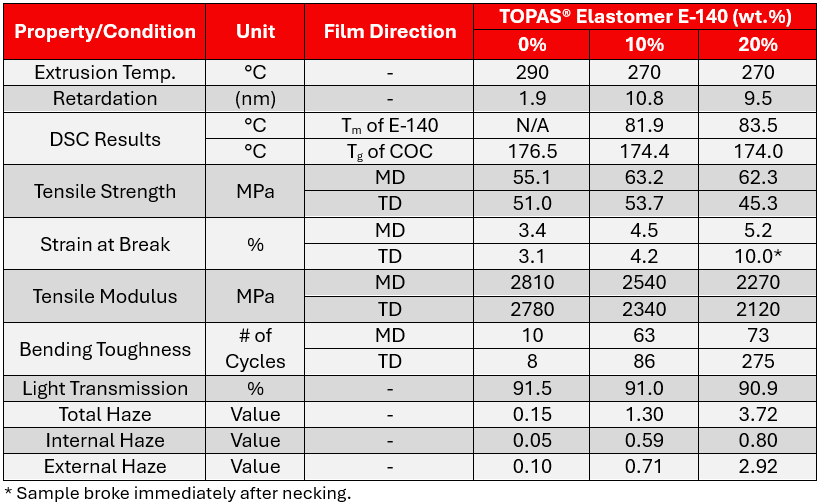

The result of blending TOPAS® Elastomer E-140 into COC was a nearly linear reduction in modulus and significant increases in bending toughness. Results for both COC grades tested can be found in Tables 2 and 3 below.

Table 2: Properties of TOPAS® COC 6015S-04 blended with TOPAS® Elastomer E-140.

Table 3: Properties of TOPAS® COC 6017S-04 blended with TOPAS® Elastomer E-140.

The Tensile Strength, which is measured at break, for the blended films remained generally constant or increased slightly. The exception to this being the TD Tensile Strength for the 20% loadings of E-140 into both 6015S-04 and 6017S-04 where the value decreased by about 15%. This is likely due to the film yielding and necking rather than undergoing a brittle failure.

The DSC results show that the E-140 plasticizes the amorphous COC phase slightly, but not significantly. The 1°C reduction in Tg 6015S-04 measured when adding 20% E-140 is not likely to cause significant change in heat resistance. And while the decrease in Tg 6017S-04 with 20% E-140 is 2.5°C compared to the control, the Tg is still 174°C for the toughened blend.

It is interesting that the internal haze remains much lower than the external haze. This indicates that the E-140 crystals at the surface are the drive the haze, rather than differences in refractive index inside the film.

Applications

The increased toughness that Elastomer E-140 brings to COC creates opportunities for applications that need the modulus, the high temperature resistance, and the purity of COC but need more toughness than would otherwise be available. Commercial uses of TOPAS® Elastomer E-140 and TOPAS® COC 6015S-04 or 6017S-04 blends may include medical devices requiring high temperature steam sterilization, retort pouches, or applications requiring durability, high temperature resistance, and low Dk .

Processing

Blends of two TOPAS® COC resins (6015S-04 and 6017S-04) were made with 10% and 20% TOPAS® Elastomer E-140. The materials were pellet blended in the single screw extruder and subsequently extruded through a 300mm wide coat hanger die with a die gap of 0.6mm. The throughput was approximately 10kg/h and drawn down to a film of about 50µm thickness. Films with a bulk phase of 6015S-04 were extruded at 270°C when no E-140 was added, and 250°C when E-140 was added. Films made from 6017S-04 were extruded at 290°C when no E-140 was added, and 270°C when E-140 was added.

Evaluation Methods

All testing was completed at Polyplastics’ TSC in Fuji, Japan. Films were evaluated for Tensile Strength, Elongation, and Modulus of Elasticity using standard JIS K7127, Bending Toughness using JIS P8115, and Haze using JIS K7105. For internal haze, the haze was measured on a film sample that was submerged in polyethylene glycol in a quartz glass cell.

The reported Bending Toughness value is the count of how many times a sample can be bent to set angle before breaking. Each trip to the determined angle is a single count. For example, for a set angle of 90°, bending from the neutral position (0°) to 90° and returning to the starting position counts as two bendings. The test conditions for Bending Toughness used in this study were: 175 counts per minute, a 1000g tension, and an angle of 90°. The test standard used was JIS P8115 and was completed on a MIT Automatic Folding Endurance Tester. A comparable method is ASTM D2176.

Retardation was measured using a PA-100 2D birefringence evaluation system manufactured by Photonic Lattice Co., Ltd. The retardation of a material is calculated by multiplying the material’s thickness by its birefringence.

For more information about TOPAS® COC resins, including Elastomer E-140, reach out to us via the Contact Us or Find a Rep links at the top of every page on our website.