Executive Summary

Blends of TOPAS® COC, three polypropylenes, and additives were made via twin-screw extrusion compounding and subsequently injection molded into test specimens. The physical properties of the blends were then measured. Generally, TOPAS® COC increased the tensile strength at break, the flexural strength, the flexural modulus, and the heat distortion temperature of the polypropylene resins and decreased their tensile strain at break and Charpy impact strength. The best blend properties were obtained when the viscosity of the polypropylene and TOPAS® COC were more closely matched and when the polypropylene used in a blend had higher strain at break and Charpy impact strength properties.

Introduction

TOPAS® Cyclic Olefin Copolymers (COC) are rigid, amorphous polyolefins with glass transition temperatures (Tg’s) ranging from 65°C to 178°C. The impact of blending COC into polyethylene is generally well known, but there is less information available on blends of COC and polypropylene. This report summarizes the physical property results of a study where COC and polypropylene blends were made.

Materials

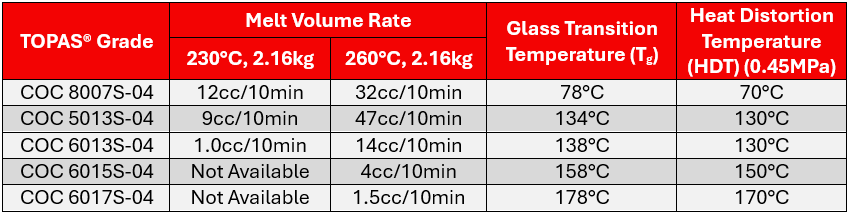

The COC resins used in this study were 8007S-04, 5013S-04, 6013S-04, 6015S-04, and 6017S-04. Basic information about these grades is given below in Table 1:

Table 1: Melt Volume Rate, Glass Transition Temperature, and HDT for the TOPAS® grades used in this study.

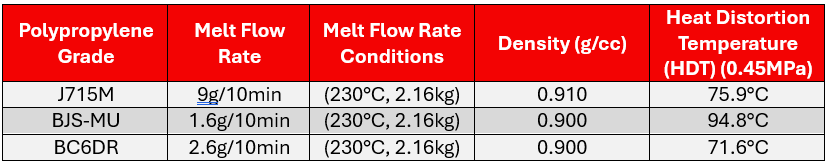

The polypropylene resins used in the study were J715M and BJS-MU, both from Prime Polymer Co., Ltd., and Novatec® BC6DR, an impact copolymer polypropylene from Japan Polypropylene Corporation. Basic information about these grades is given below in Table 2:

Table 2: Melt Flow Rate, Density, and HDT for the polypropylene grades used in this study.

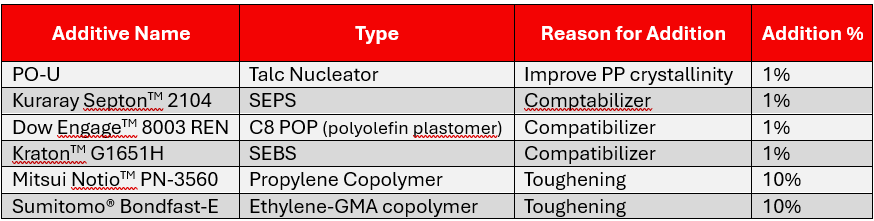

In addition to the COC and polypropylene, six materials were used as additives. These materials are listed below in Table 3.

Table 3: Additive name, material type, and the reason for adding it to the blends.

Results & Discussion

TOPAS® COC 5013S-04 & 6013S-04 at 10%, 20%, and 30% in J715M

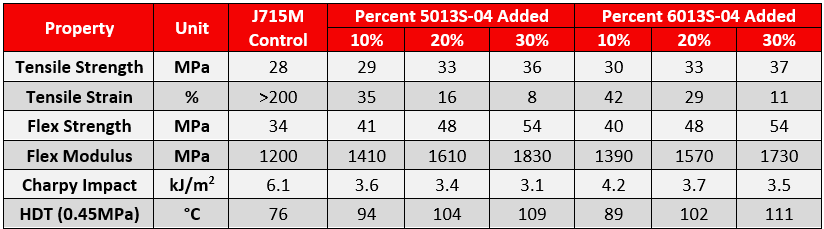

TOPAS® COC Grades 5013S-04 and 6013S-04 were added at 10%, 20% and 30% into J715M polypropylene. Tensile strength at break, flexural strength, flexural modulus, and heat distortion temperature increased with each loading level of COC. The reduction in tensile strain is expected because COC resins have single digit strain at break values. The result of adding even 10% COC to J715M showed a decline of approximately 33% in Charpy impact strength, although increasing the loading to 30% COC did not reduce the Charpy impact strength significantly further. Tensile strain at break decreased markedly even at 10% COC and then by about an additional 50% for each step up in loading level.

The differences between adding 5013S-04 versus 6013S-04 to J715M were relatively minor. TOPAS® COC 5013S-04 addition resulted in lower impact strengths and strain at break values compared to using TOPAS® COC 6013S-04. The other properties, tensile strength at break, flexural strength, flexural modulus, and heat distortion temperature were approximately equivalent. Table 4, below, contains the physical property data for this set.

Table 4: Physical properties of J715M polypropylene with 10%, 20%, and 30% TOPAS® COC 5013S-04 & 6013S-04.

TOPAS® COC 8007S-04, 5013S-04, 6013S-04, and 6015S-04 at 20% in J715M

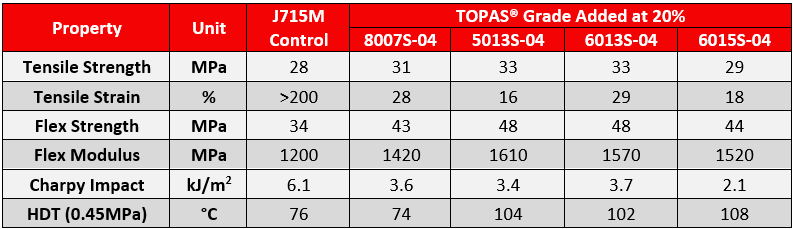

TOPAS® COC grades 8007S-04 and 6015S-04 were added to J715M at a 20% loading. The addition of the lower Tg grade, 8007S-04 increased the tensile strength at break, flexural strength and flexural modulus, but the heat distortion temperature decreased slightly. When 6015S-04 was added to J715M, the same three properties and the heat distortion temperature increased. The decrease in the tensile strain at break and Charpy impact strength properties were more pronounced when adding 6015S-04 than 8007S-04. When adding in 5013S-04 and 6013S-04 to the comparison, 6013S-04 stands out as the best balance of property changes. Note that this was true for adding these COC grades to J715M, a polypropylene with a 9cc/10min melt flow rate. This data can be found below in Table 5.

Table 5: Physical properties of J715M propylene with 20% TOPAS® COC 8007S-04, 5013S-04, 6013S-04, and 6015S-04.

TOPAS® COC 6015S-04 at 20% in J715M with Additives

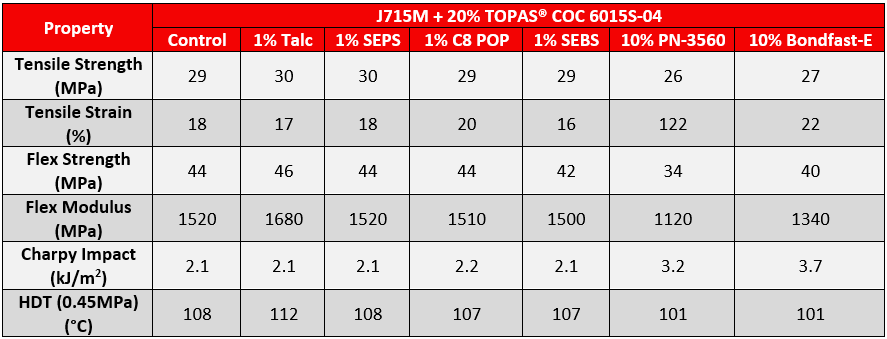

A series of different additives were incorporated into a blend of J715M and 20% 6015S-04 to determine their impact on the physical properties of the blend. A talc additive was used at a 1% loading to increase the crystallinity of the polypropylene. Three additives (Kuraray SeptonTM 2104 “SEPS”, Dow EngageTM 8003 REN and KratonTM G1651H) were used at a 1% loading to increase the compatibility between the COC and polypropylene phases. And then two additives (Mitsui Chemical NotioTM PN-3560 and Sumitomo® Bondfast-E) were added at a 10% loading to add toughening to the blend.

The addition of talc to the blend of J715M and 20% 6015S-04 increased the heat distortion temperature by four degrees and increased the flexural modulus by ten percent. The compatibilizing additives had minimal effect on all properties. And the toughening additives caused reductions in tensile properties, flexural properties, and heat distortion temperature. The NotioTM PM-3560 did increase the tensile strain at break by 6x compared to the control blend, but the Charpy impact strength did not see such a dramatic increase. These results can be found in Table 6, below.

Table 6: Physical properties of J715M with 20% 6015S-04 and compatibilizers or elastomers. Control has no additional additives.

TOPAS® COC Resins at 20% in Polypropylenes BJS-MU and NovatecTM BC6DR

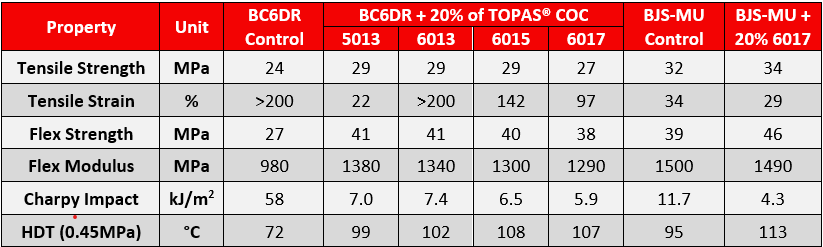

Polypropylene Novatec® BC6DR from Japan Polypropylene Corporation was blended with 20% of TOPAS® COC 5013S-04, 6013S-04, 6015S-04, and 6017S-04. Additionally, polypropylene BJS-MU from Prime Polymer Co., Ltd. was blended with 20% TOPAS® COC 6017S-04. These polypropylenes have lower melt flow rates, or higher viscosities, than the J715M that was used in the earlier blend work.

The blends with Novatec® BC6DR had significantly improved tensile strain at break as compared to earlier blends using J715M, with the exception being the blend with TOPAS® COC 5013S-04 where there was improvement but not as significant. A similar improvement in Charpy impact exists as well. These improvements are likely because Novatec® BC6DR already had a higher Charpy impact strength than J715M and because its viscosity is a closer match to those of the COC resins.

The blend of BJS-MU from Prime Polymer Co., Ltd. with TOPAS® COC 6017S-04 resulted in a material with an improved heat distortion temperature and flexural strength and a reduce Charpy impact strength, but the tensile properties and flexural modulus were similar to the control.

The data for these blends can be found in Table 7, below.

Table 7: Physical properties of NovatecTM BC6DR polypropylene control and with 20% TOPAS® COC 5013S-04, 6013S-04, 6015S-04, and 6017S-04. Also included are the physical properties of BJS-MU polypropylene control and with 20% 6017S-04.

Conclusion

Across all the data sets it is clear that TOPAS® COC increases the strength and heat resistance properties of polypropylene. The tradeoff is in the toughness properties, which was shown through Charpy impact strengths and tensile strain at break. The final dataset shown in Table 7 illustrates that viscosity matching between the polypropylene phase and the COC phase is important for obtaining the best balance of properties. The higher viscosity NovatecTM BC6DR polypropylene blend with 20% TOPAS® COC 6013S-04 outperformed the control J715M material in all six physical properties.

Sample Preparation

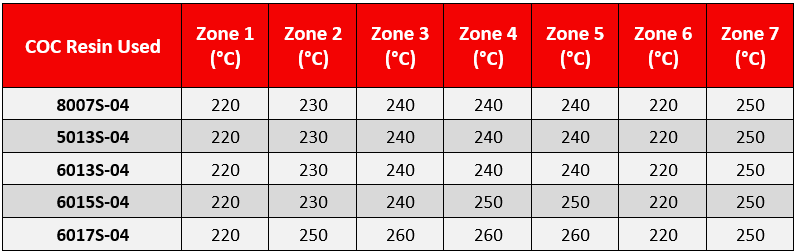

The sample blends were prepared in a twin-screw extrusion compounding line that utilized different temperature conditions depending on the grade of TOPAS® COC that was utilized. The screw rotation speed was 150RPM. And the throughput of the line was set to 10kg/h. The temperature conditions for compounding are given below in Table 8.

Table 8: Barrel temperature settings for compounding the different blends used in the study.

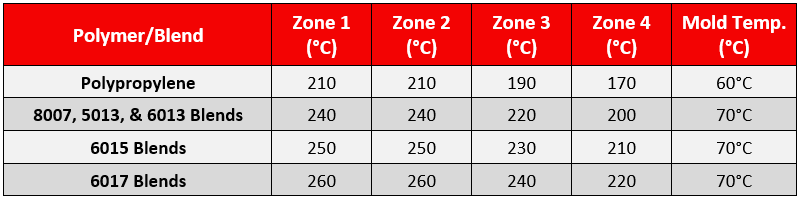

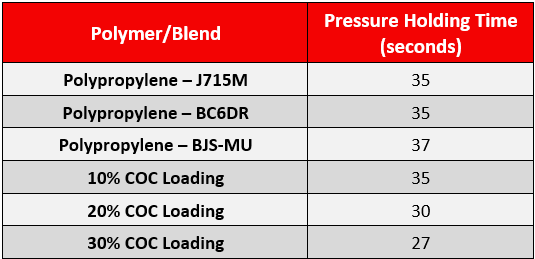

The compounded blends were then injection molded into ISO tensile and bending test pieces. The screw speed was 100rpm, back pressure of 8MPa, injection speed of 16.7mm/sec, cooling time of 10 seconds, and pull back of 3mm. Tables 9 and 10, below, have temperature and pressure holding time information is below:

Table 9: Injection molding extrusion and mold temperatures for the studied materials.

Table 10: Pressure holding time for the studied materials.

Note that the pressure holding time was able to be reduced for increased loadings of COC in polypropylene. This is because the amorphous nature of COC does not require extensive holding time to build crystallinity.

Applications

Based on the data presented in this report, blends of polypropylene and TOPAS® COC resins can be used to increase the strength and heat distortion properties of polypropylene. Areas where this may be of use include:

- Applications where clean cutting of hot polyolefins is difficult (e.g., form-fill-seal and die-cutting of thermoformed parts) could be improved by adding COC to increase the tensile modulus and reduce stringiness.

- Hot-filled food packaging applications could be improved by adding COC to increase the dimensional stability of the package at high temperature. This could increase cycle times, enable recyclability via elimination of non-polyolefin high stiffness materials, and reduce the variation in repeat length that might cause fill weight issues.

- Thermoforming applications could be improved by adding COC to increase the modulus of the formed part while semi-crystalline polyolefin is still crystallizing. This could reduce part weight through higher modulus, and reduced cycle times through temperature dependent (not crystallization-dependent) stiffness.

- Retort packaging could be improved by adding COC to prevent film deformation during the retort process

While not explored in this study, an alternative method of incorporating COC is through multilayer coextrusion. This can allow for the COC phase to further enhance the physical and thermal properties.

For more information about TOPAS® COC resins reach out to us via the Contact Us or Find a Rep links at the top of every page on our website.