Executive Summary

The tensile properties of three TOPAS® COC resins, 6013S-04, 6015S-04, and 6017S-04, were measured at temperatures up to 18°C below their glass transition temperatures. The results reveal that these COC resins retain two-thirds or more of their room temperature tensile modulus at the highest temperatures measured. This data highlights the advantages that COC can bring to polyolefin packaging applications and to applications requiring high temperature resistance and clarity.

Introduction

TOPAS® Cyclic Olefin Copolymers (COC) are rigid, amorphous polyolefins with glass transition temperatures (Tg’s) ranging from 65°C to 178°C. The high glass transition temperature grades of TOPAS® COC (6013S-04, 6015S-04, and 6017S-04) maintain a high tensile modulus even at high temperatures. Exactly how much tensile strength is maintained as the temperature increases is the question explored in this report.

Materials

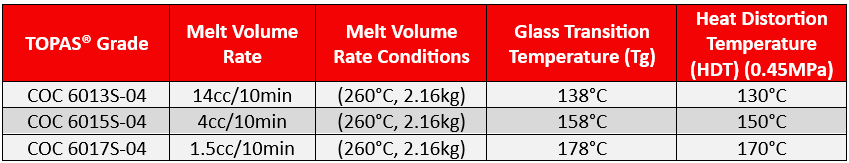

TOPAS® COC resins are amorphous copolymers of ethylene and norbornene that are used on their own or as a blend component with other polyolefins to adjust performance characteristics. The COC resins that were evaluated were 6013S-04, 6015S-04, and 6017S-04. These resins are commonly used in medical and diagnostic applications for their purity, dimensional stability, and outstanding transparency. Basic information for these three grades is given below in Table 1:

Table 1: Melt Volume Rate, Tg, and HDT for the TOPAS® grades used in this study.

Results

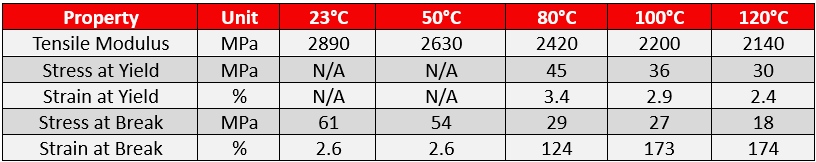

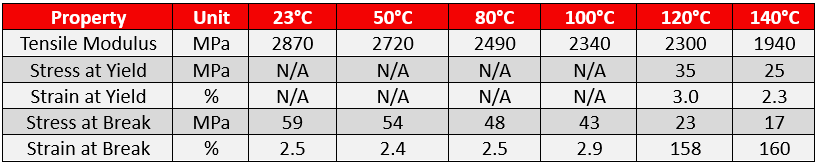

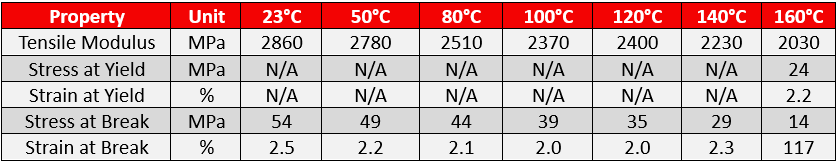

The tensile properties of TOPAS® COC 6013S-04, 6015S-04, and 6017S-04 injection molded tensile bars were measured at 23°C, 50°C, 80°C, 100°C, and 120°C. The measurements were also made at 140°C for 6015S-04 and 6017S-04, and at 160°C for 6017S-04. The results of these tensile tests are given below in Tables 2, 3 and 4.

Table 2: Tensile Properties of TOPAS® COC 6013S-04 from 23°C to 120°C

Table 3: Tensile Properties of TOPAS® COC 6015S-04 from 23°C to 140°C

Table 4: Tensile Properties of TOPAS® COC 6017S-04 from 23°C to 160°C

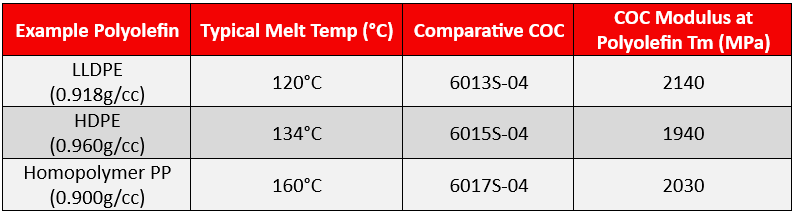

The tensile testing shows that the three grades of COC maintain over 67% of their room temperature modulus at a temperature that is 18°C below their glass transition temperature. This means that when other polyolefins are melting, these COC resins still have a modulus around 2GPa. A comparison of polyolefins against COC is below in Table 5.

Table 5: Common Polyolefins and their melt temperature alongside the modulus of the three analyzed TOPAS® COC resins at approximately that melt temperature.

Applications

Based on this data, neat COC resin can be of use in applications where retention of high modulus at elevated temperatures is desired while maintaining clarity. Additionally, blends or multi-layer coextrusions of COC and other polyolefins could be made to increase the high temperature performance characteristics. Examples of the latter include:

- Hot-filled food packaging applications could be improved by adding COC to increase the dimensional stability of the package at high temperature. This could increase cycle times, enable recyclability via elimination of non-polyolefin high stiffness materials, and reduce the variation in repeat length that might cause fill weight issues.

- Thermoforming applications could be improved by adding COC to increase the modulus of the formed part while semi-crystalline polyolefin is still crystallizing. This could reduce part weight through higher modulus, and reduced cycle times through temperature dependent (not crystallization-dependent) stiffness.

- Applications where clean cutting of hot polyolefins is difficult (e.g., form-fill-seal and die-cutting of thermoformed parts) could be improved by adding COC to increase the tensile modulus and reduce stringiness.

- Retort packaging could be improved by adding COC to prevent film deformation during the retort process.

For more information about TOPAS® COC resins reach out to us via the Contact Us or Find a Rep links at the top of every page on our website.