9506F-500

Typ für die Folienextrusion mit verbessertem Verarbeitungsverhalten. Niedrige Tg, geeignet für viele Schrumpffolienanwendungen. Kann in Mehrschichtfolien als einzelne Schicht oder in Mischungen mit PE verwendet werden.

8007F-600

Extrusionstyp für Gieß- und Blasfolien mit den meisten Eigenschaften von 8007F-04 und verbessertem Verarbeitungsverhalten.

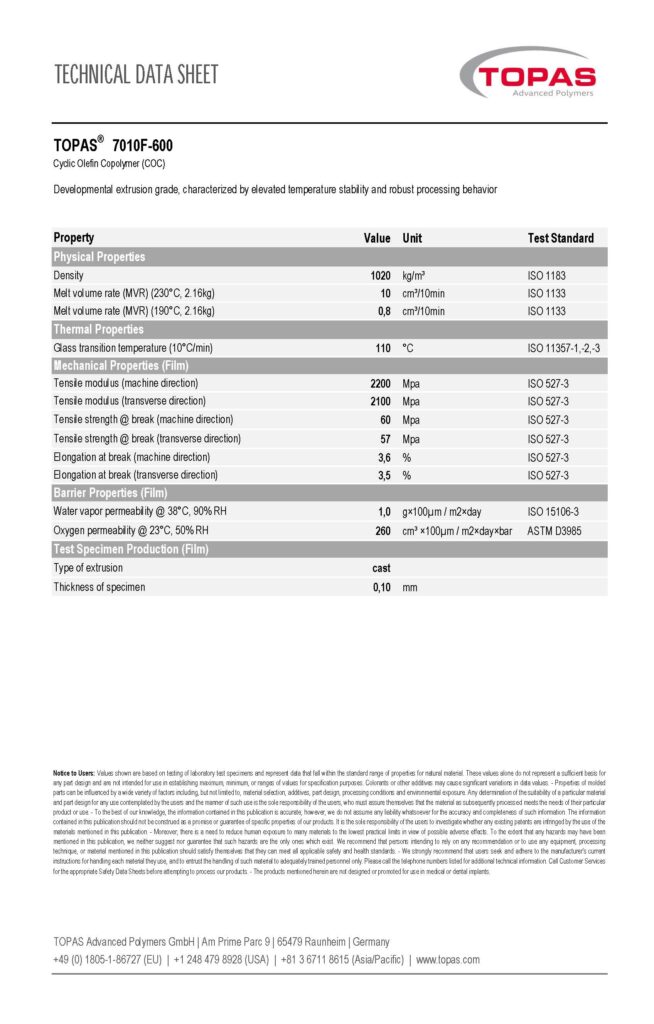

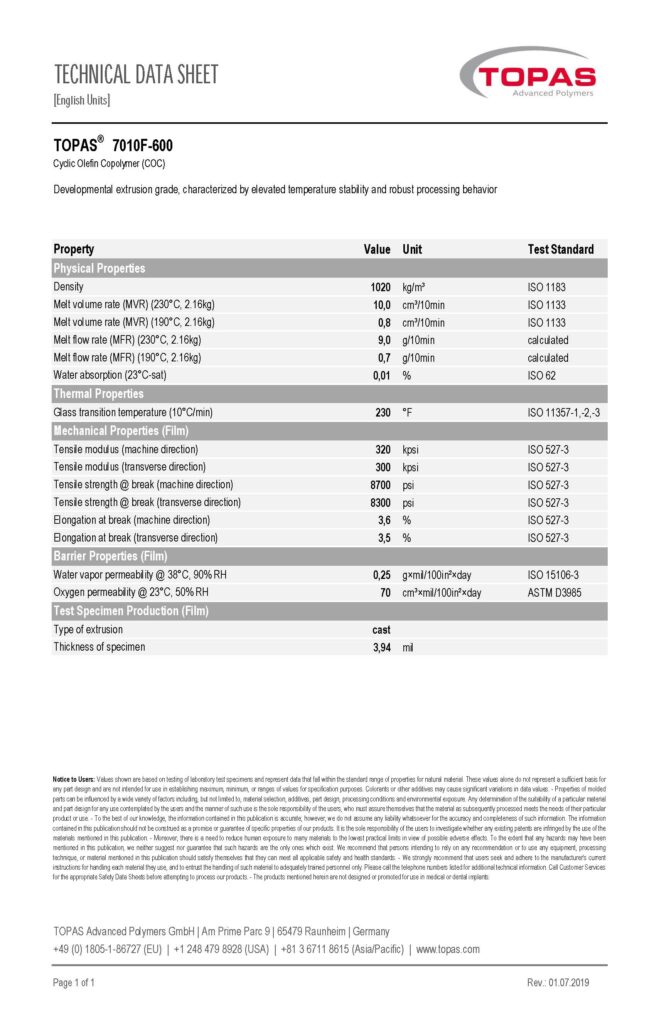

7010F-600

Polyolefin / COC Blends

Most grades of TOPAS® can be extruded in blends on a variety of commercial blown and cast film lines.

Elastomer E-140

This grade can be extruded on a variety of commercial cast and blown film lines as a monolayer, in blends or as a discrete layer in coextrusion.

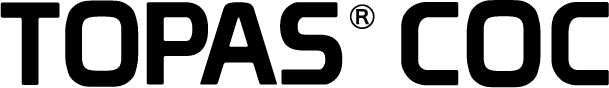

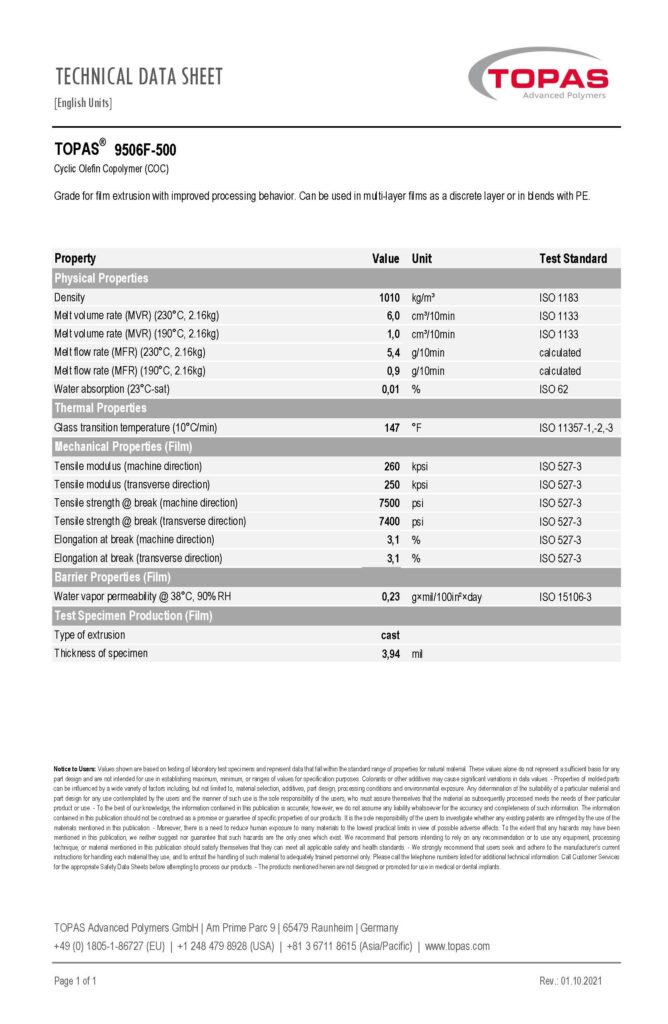

9506F-500

Grade for film extrusion with improved processing behavior. Low Tg suitable for many shrink film applications. Can be used in multi-layer films as a discrete layer or in blends with PE.

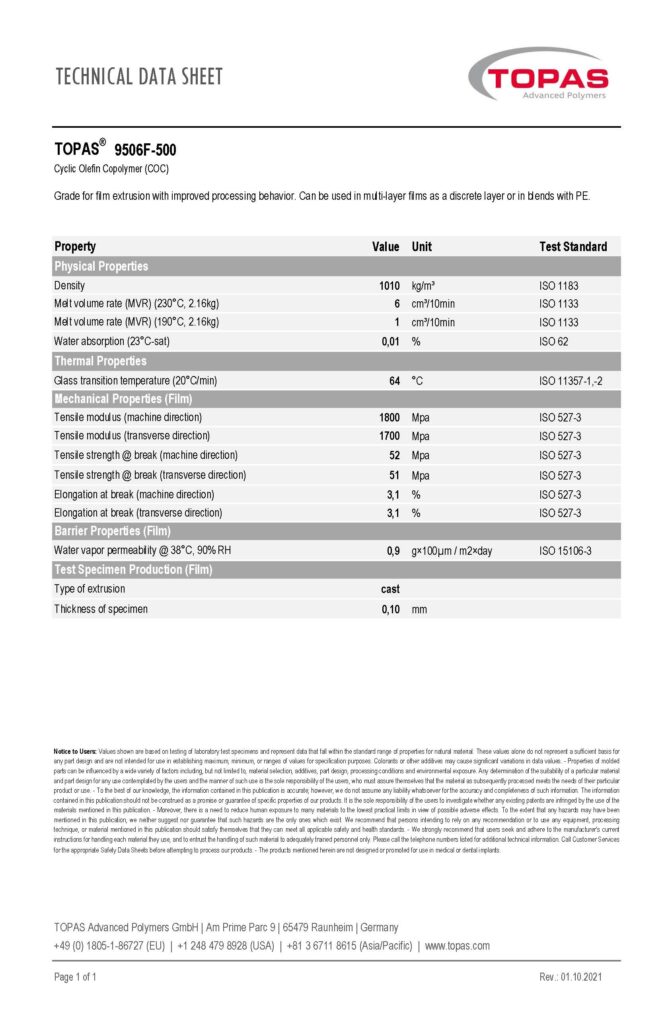

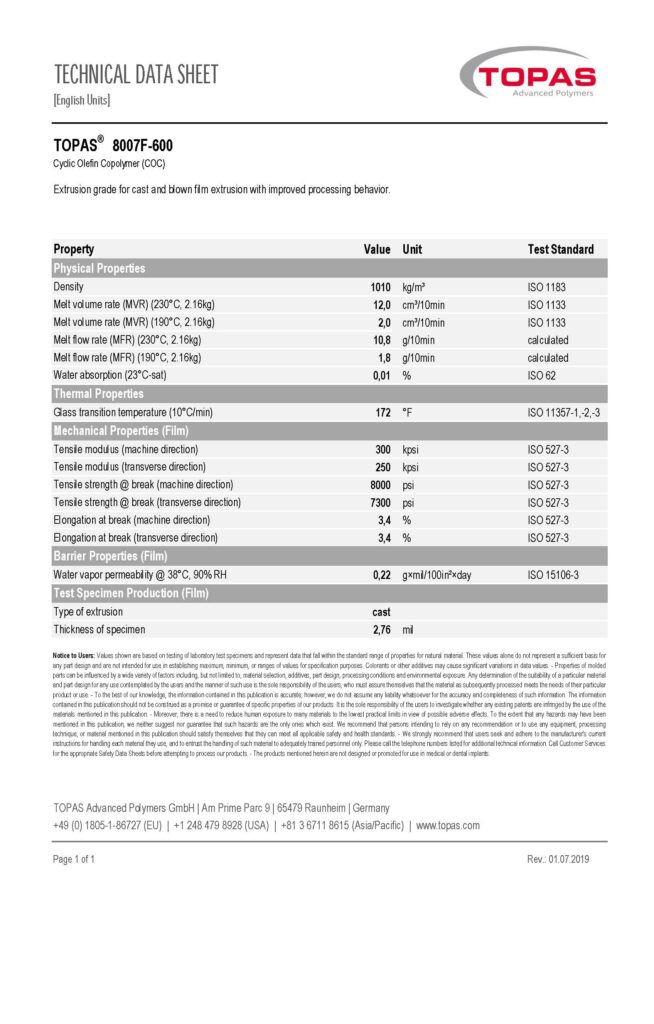

8007F-600

Extrusion grade for cast and blown film featuring most attributes of 8007F-04, with improved processing behavior.

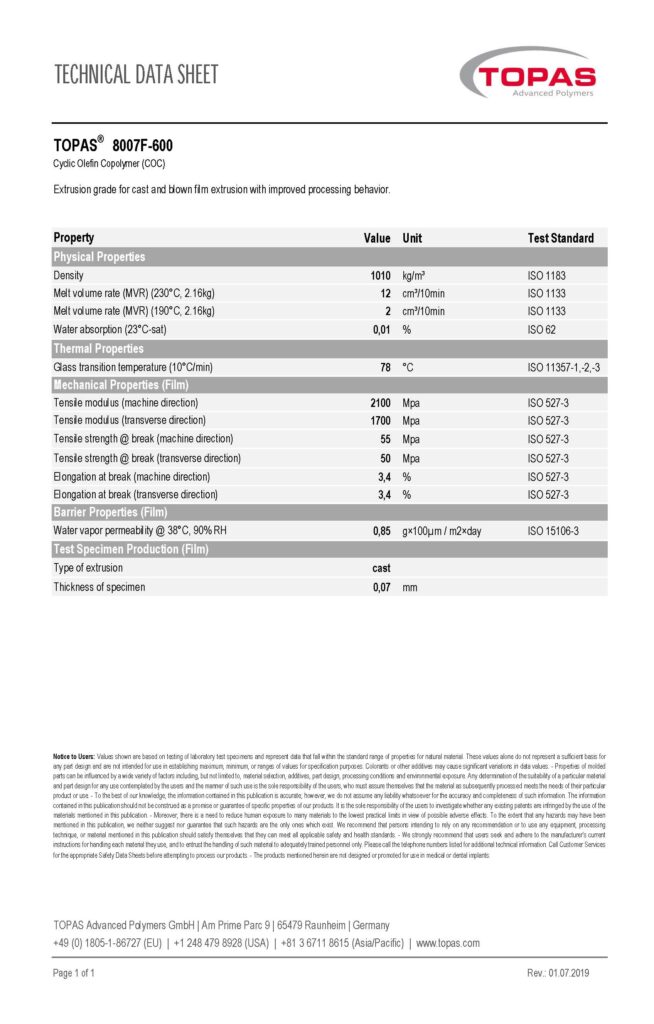

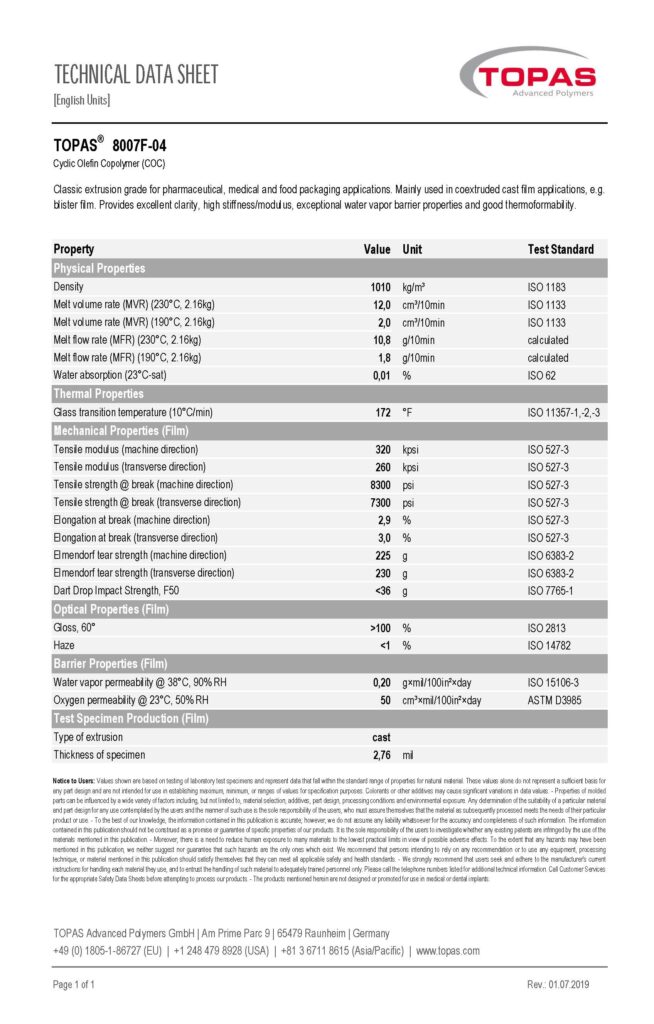

8007F-04

Classic extrusion grade for pharmaceutical, medical and food packaging applications. Mainly used in coextruded cast film applications, e.g. blister film. Provides excellent clarity, high stiffness/modulus, exceptional water vapor barrier properties and good thermoformability.

7010F-600

Developmental extrusion grade, characterized by elevated temperature stability and robust processing behavior.

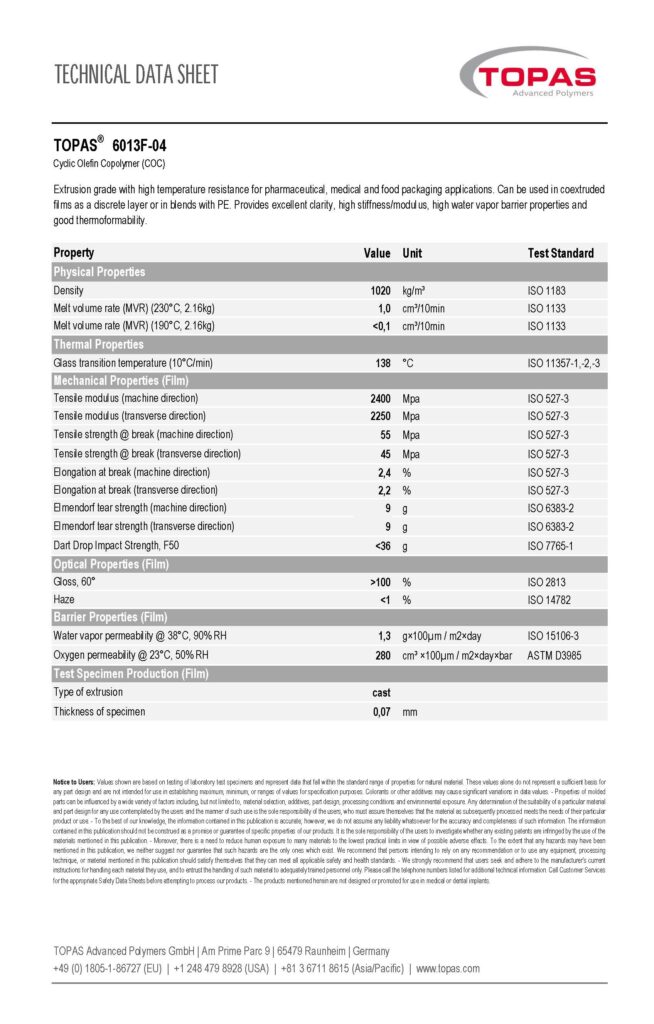

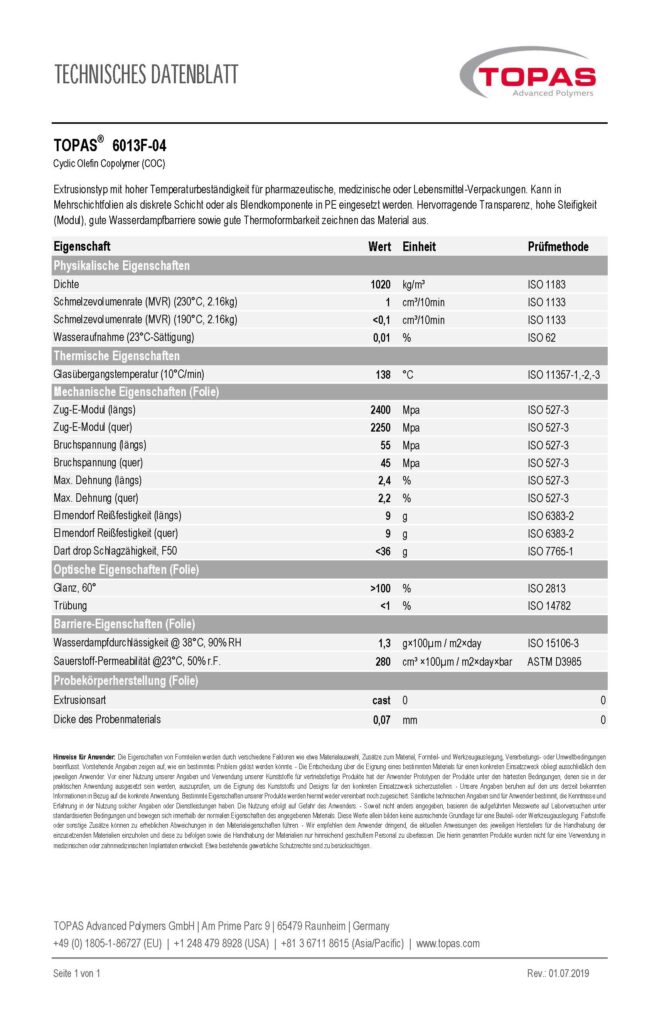

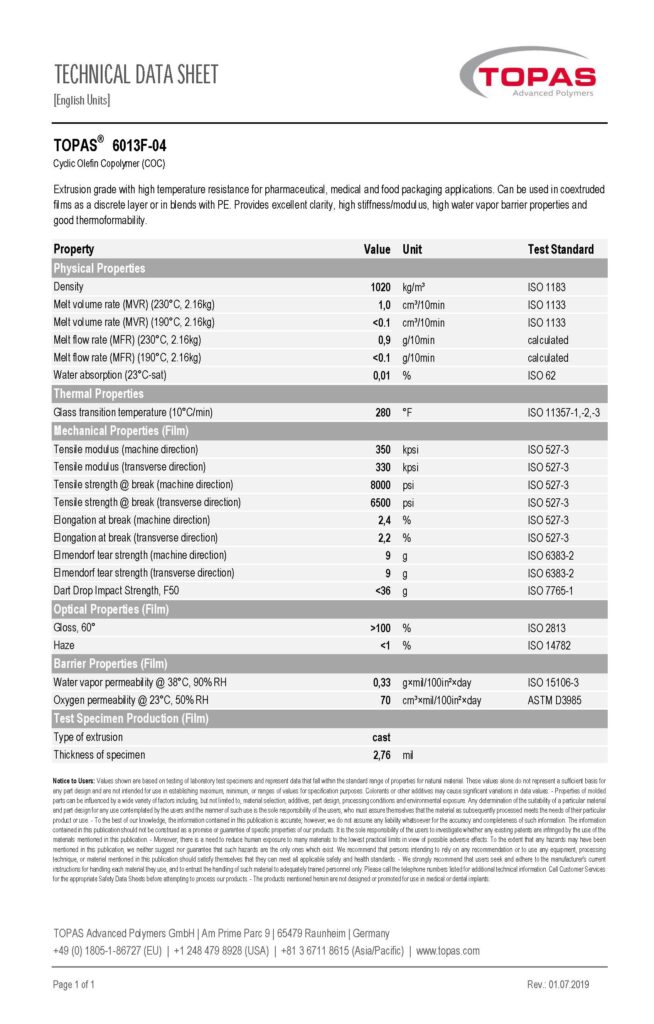

6013F-04

Extrusion grade with high temperature resistance for pharmaceutical, medical and food packaging applications. Can be used in coextruded films as a discrete layer or in blends with PE. Provides excellent clarity, high stiffness/modulus, high water vapor barrier properties and good thermoformability.

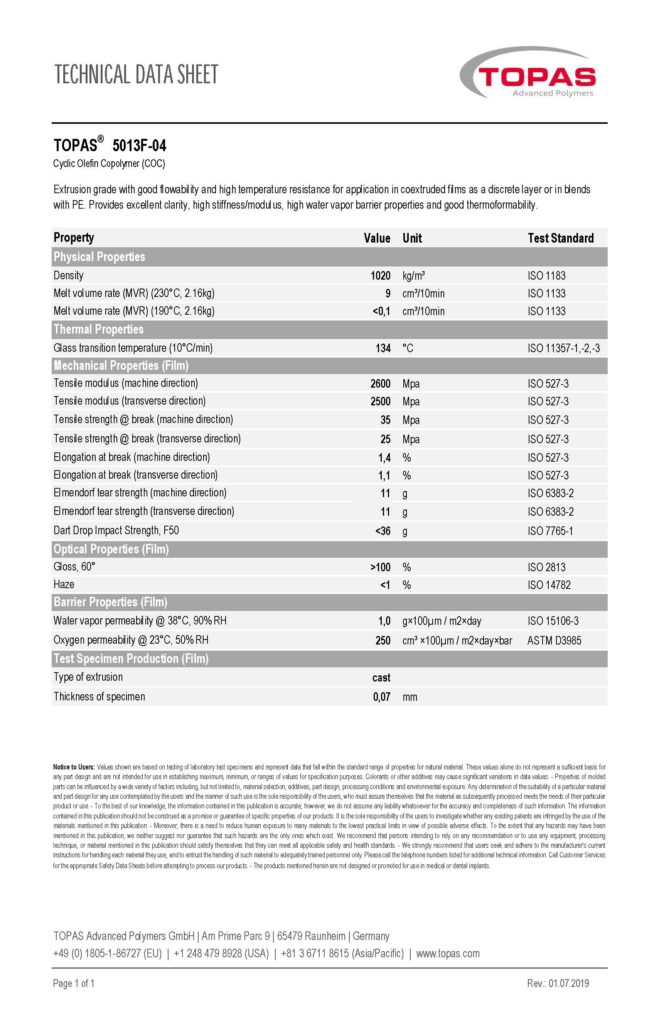

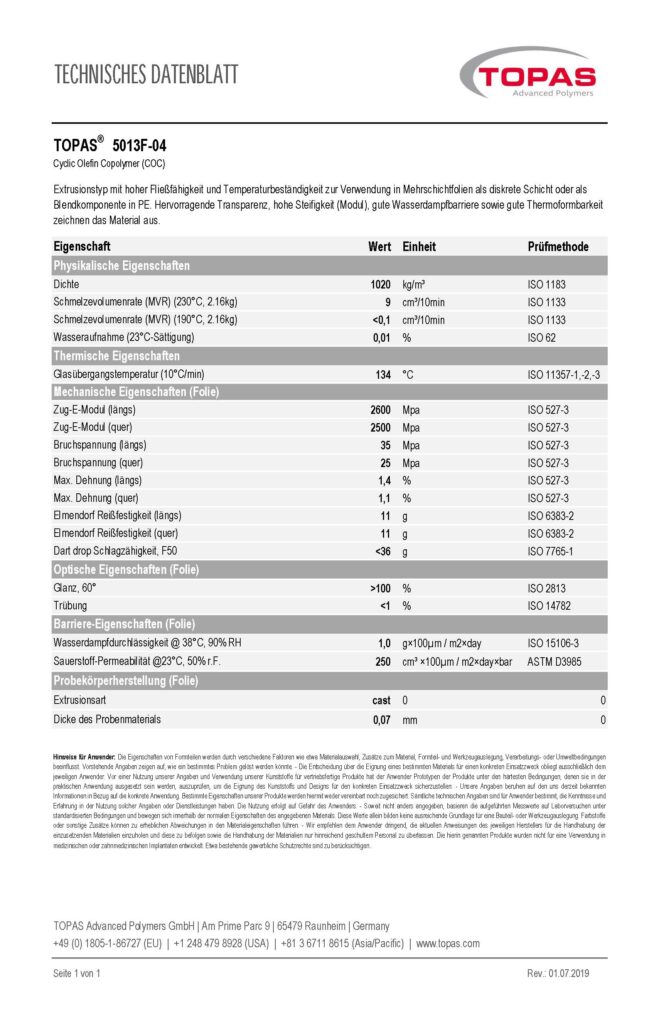

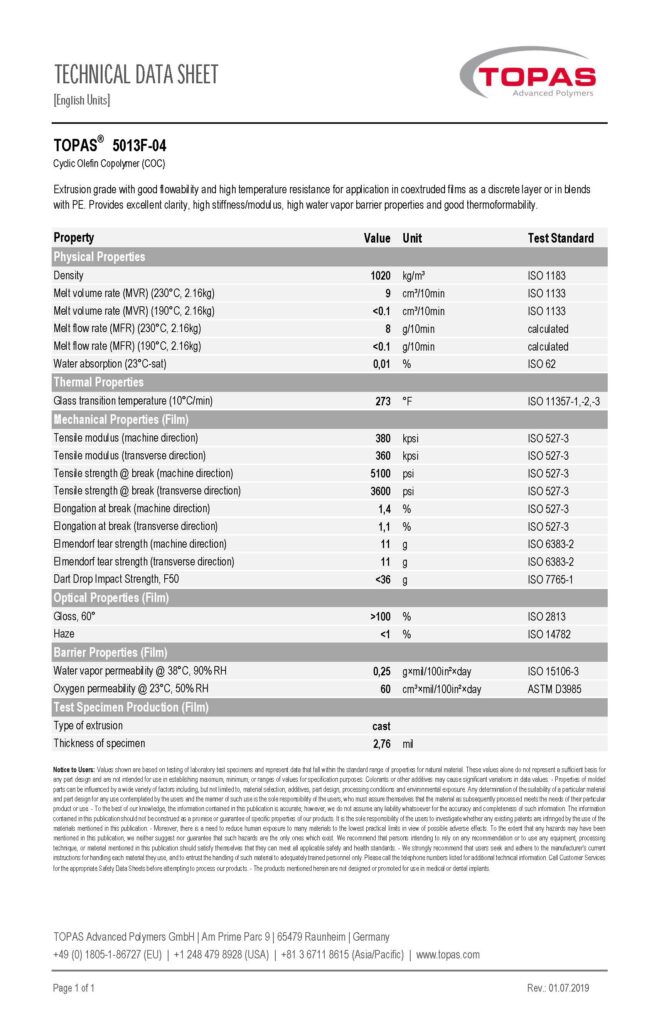

5013F-04

Extrusion grade with good flowability and high temperature resistance for application in coextruded films as a discrete layer or in blends with PE. Provides excellent clarity, high stiffness/modulus, high water vapor barrier properties and good thermoformability.

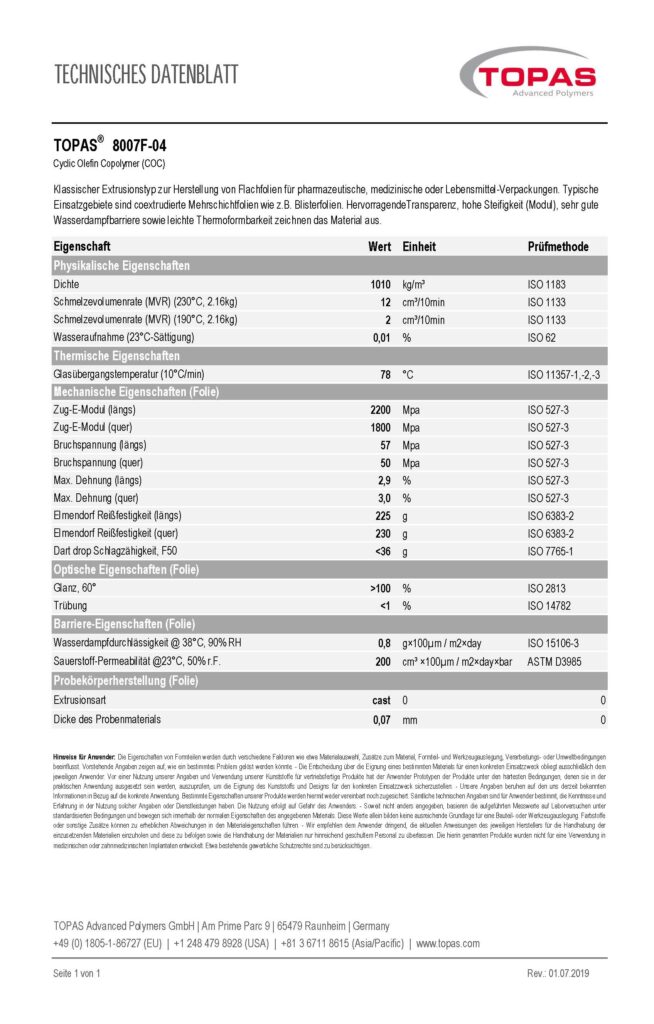

8007F-04

Klassischer Extrusionstyp zur Herstellung von Flachfolien für pharmazeutische, medizinische oder Lebensmittel-Verpackungen. Typische Einsatzgebiete sind coextrudierte Mehrschichtfolien wie z.B. Blisterfolien. HervorragendeTransparenz, hohe Steifigkeit (Modul), sehr gute Wasserdampfbarriere sowie leichte Thermoformbarkeit zeichnen das Material aus.

6013F-04

Extrusionstyp mit hoher Temperaturbeständigkeit für pharmazeutische, medizinische oder Lebensmittel-Verpackungen. Kann in Mehrschichtfolien als diskrete Schicht oder als Blendkomponente in PE eingesetzt werden. Hervorragende Transparenz, hohe Steifigkeit (Modul), gute Wasserdampfbarriere sowie gute Thermoformbarkeit zeichnen das Material aus.

5013F-04

Extrusionstyp mit hoher Fließfähigkeit und Temperaturbeständigkeit zur Verwendung in Mehrschichtfolien als diskrete Schicht oder als Blendkomponente in PE. Hervorragende Transparenz, hohe Steifigkeit (Modul), gute Wasserdampfbarriere sowie gute Thermoformbarkeit zeichnen das Material aus.

9506F-500

Grade for film extrusion with improved processing behavior. Low Tg suitable for many shrink film applications. Can be used in multi-layer films as a discrete layer or in blends with PE.

8007F-600

Extrusion grade for cast and blown film featuring most attributes of 8007F-04, with improved processing behavior.

8007F-04

Classic extrusion grade for pharmaceutical, medical and food packaging applications. Mainly used in coextruded cast film applications, e.g. blister film. Provides excellent clarity, high stiffness/modulus, exceptional water vapor barrier properties and good thermoformability.

7010F-600

Developmental extrusion grade, characterized by elevated temperature stability and robust processing behavior.

6013F-04

Extrusion grade with high temperature resistance for pharmaceutical, medical and food packaging applications. Can be used in coextruded films as a discrete layer or in blends with PE. Provides excellent clarity, high stiffness/modulus, high water vapor barrier properties and good thermoformability.

5013F-04

Extrusion grade with good flowability and high temperature resistance for application in coextruded films as a discrete layer or in blends with PE. Provides excellent clarity, high stiffness/modulus, high water vapor barrier properties and good thermoformability.